Sun Sara believes: To be the best beauty supplier in China.

Sun Sara Cosmetics is established in 2012 in Canada. Then sets up the branch company gradually, HongKong, Spain, and Guangzhou Which have our main Marketing department and the Professional Manufacturer which is 6,000 square meters with the highest European standard approval GMPC certificate. Our Manufacturer is strict with the ISO 22716:2007 Cosmetics line regulate our daily procedure based on these Eight Systems: R&D, Supply, Production Management, Packing, Inventory, QC Pre-shipment service, and After-Sale service.

For the future target, we hope to root in the hair care products at the same time, will be part of the energy into the body care, facial care products research and development, for helping the “beauty” people all over the world.

R&D System:

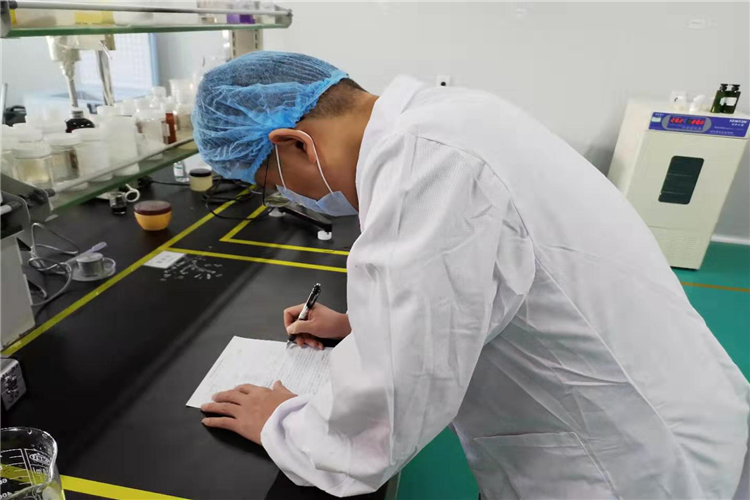

As a Cosmetics Manufacturer, the key point is R&D department. Up till now, our R&D department already launch 11 new brand formulas and gain a certain fame all around the world. Annual, our technician invent more than 3,000 formulas for our customers who want to build a new brand and win a big success in the market of customers. To develop the new products we are not just choose the suitable raw material but also do the following test to ensure every formula is qualified.

And we are also pay attention to the cleanliness of the laboratory, as you can notice that everyone who been to the laboratory must be sanitizing and wear a whole protection suits. That’s regulate procedure for the GMPC standards, also can make sure not evolve the formulas.

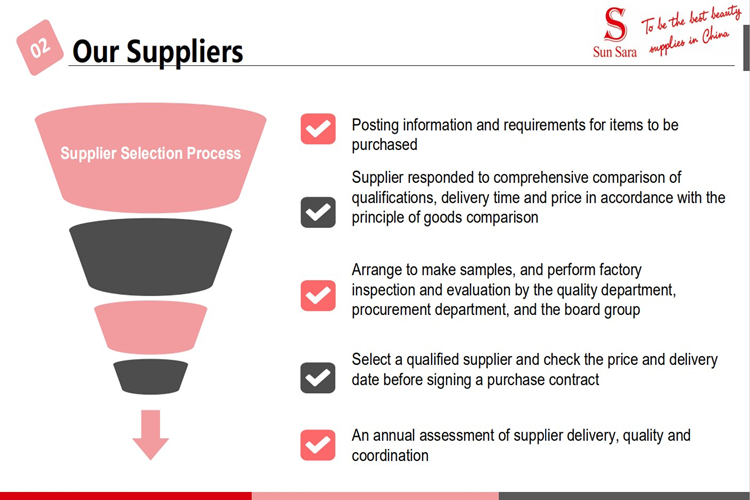

Supply System:

Numerous of the customers said that “Choose a befitting and realiable supplier which is half sucess of the project which will less 2/3 problems.” Sun Sara believes we are the one you are always seeking.

For the suppliers of the raw material we always cooperate with the well-known and reliable company, such as the DOW, Clariant, DSM, Shino-tech, SOLVAY, Firmenic etc. Through this years we are keeping searching the most suitable and the innovative suppliers that’s also the reason we are always keeping establish the new formulas to meets the customers requirements and offer variety of new througths.

Production Management System:

For the production Management there are 3 important points, the Employee, the Equipment and the IQPC.

The each employee we will have the pre-employment training and each month will have the 3-5 times other basic training. To keep all of us is professional.

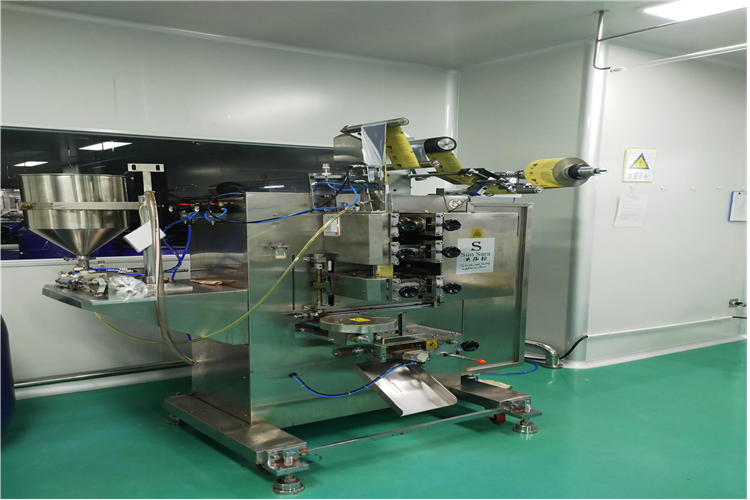

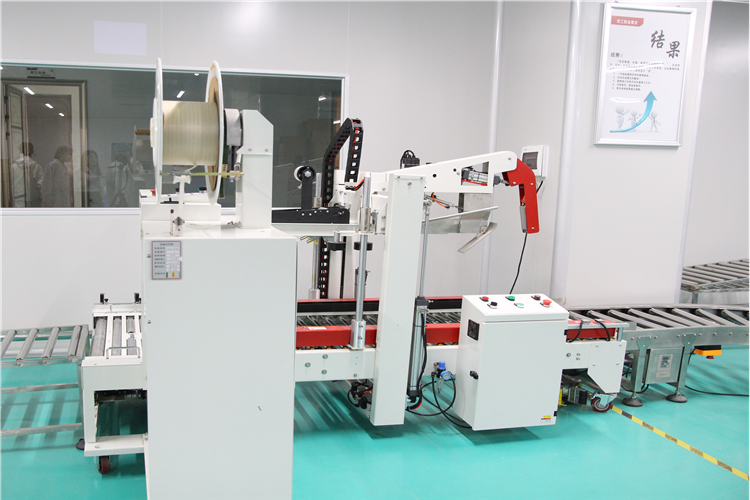

For the equipment, currently,we have the biggest emulsifying machine is 2 tons,the 4 full automatic filling machine and 2 semi-automatic filling machine, automatic sachet filling machine, the form-fill-seal packaging machine and the packaging machine, all this machine is due to keep our production delivery cycle and the stable quality. Also the daily routine maintaining is must to keep the factory products regular.

The IQPC process is through the test to prevent the unqualified products, such as the test the PH detection of semi-finished product, check the first sample of the outer package etc, also all the process we will record to check every products process. When have the mistakes we can find the it immediately and find out the solutions.

Packaging System:

The good packaging will prevent lots of the damage issues also give the customers good impressions, we are also focus on that points, such as we will use the 5 class cartons, the EPE to prevent the pump broken, the automatic box sealing machine. The whole process will be spervised and recorded by our quality checking team.

Inventory System:

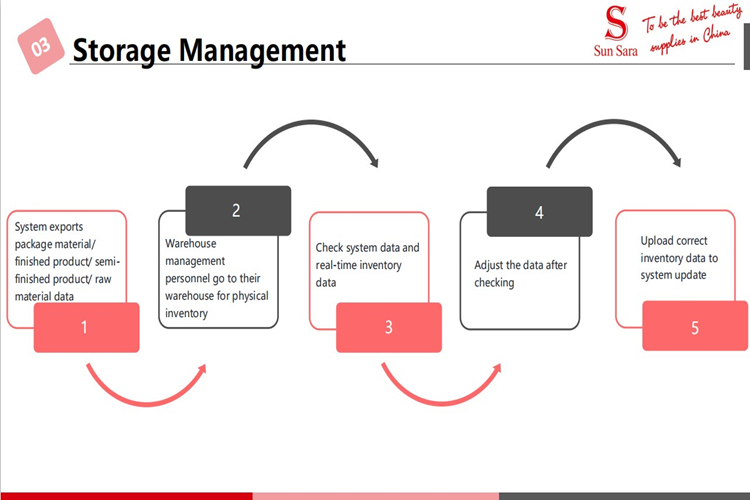

Our inventory include: the raw material warehouse, the packaging warehouse, the semi-finished products warehouse, the finished products warehouse, the above is due to manage the stocks officially. What’s more, every products is need record which is more convenient for check the stocks and the arrange the production.

The whole process which is more regulate for the inventory.

QC System:

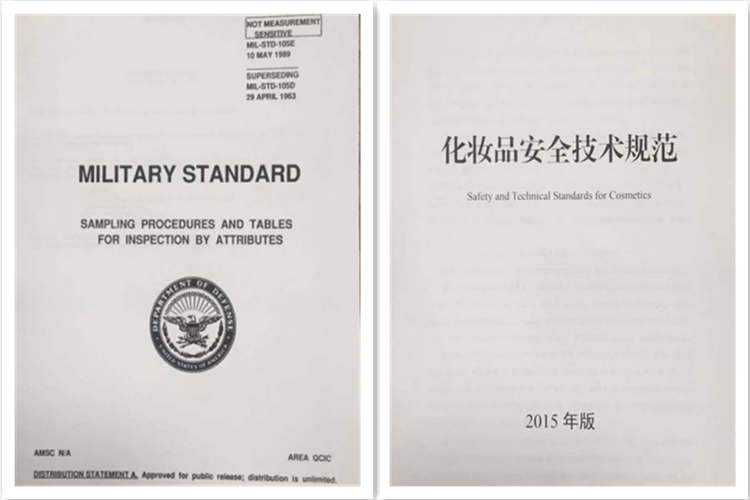

Quality mean’s everything in Cosmetics. Quality checking team will do the inspections according to the “Safety and Technical Standards for Cosmetics”&”Sampling Procedures and Tables for Inspection by Attributes” held 6 tests of the samples and the finished products through the 9 professional inspecting machine.

Apart from products quality , first impression also matter, so we have the developed packing specifications and the procedures to ensure the clear and safe transportation.

Each of the process will be operate by 5 members with 8 yeas experience on average. They haev deeply knowledge and familiar with the standards and the inspection requirements. Main purpose is to keep the every products are qualified send to the customers.

Pre-shipment Inspection System: